T7170 & T7270 Ag-Bagger

Share

The T7170 & T7270 Pull-Type Ag-Baggers feature many design enhancements to increase forage capacity including a wider conveyor, Revolutionary Rotor, forage distributer and sweeping tunnel cleanout. The T7270 features a 1000 RPM PTO while the T7170 features a 540 RPM PTO.

Features

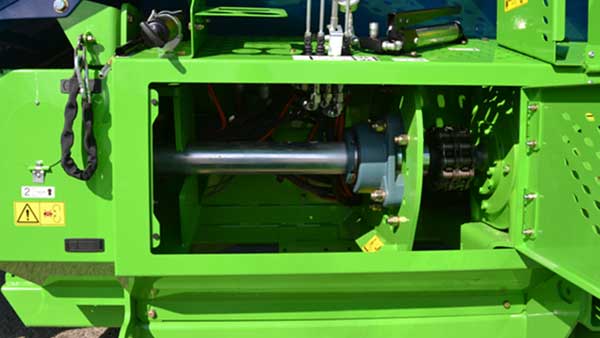

Revolutionary Rotor

The New Revolutionary Rotor has twice as many teeth across the entire rotor taking smaller bites of forage for continuous flow. With smaller bites of forage across the rotor face, this results in greater feedstuff compaction and higher density in Genuine Ag-Bags.

Sweeping Tunnel Cleanout

New for the T7170, the Sweeping Tunnel Cleanout uses hydraulic cylinders to sweep remaining crop out into the Ag-Bag when finished. This feature reduces labor, time and plastic usage when finishing and starting a new Ag-Bag.

Single Wider Conveyor

The single, wider conveyor is 12-inches wider for more capacity and faster unloading. The conveyor floor is made from stainless steel and reinforced, providing better wear resistance, long service life, reduced maintenance, and increased reliability.

Forage Distributor

The Forage Distributor evenly distributes forage over the entire Revolutionary Rotor for faster unloading and increased capacity of Genuine Ag-Bags. The Forage Distributor is hydraulically driven and features paddle tines at ends to prevent crop build-up.

Integrated Hydraulic Lift System

Standard with all T7170 models, the integrated hydraulic lift system saves time when changing between transport mode and Ag-Bagging mode. Also, manual jacks are included for when a tractor is not available to power the unit.

Removable Stripper Bar Plates

An additional benefit of the sweeping tunnel cleanout is that users have access to this area to replace the stripper bar plates either as one complete plate or in smaller sections.

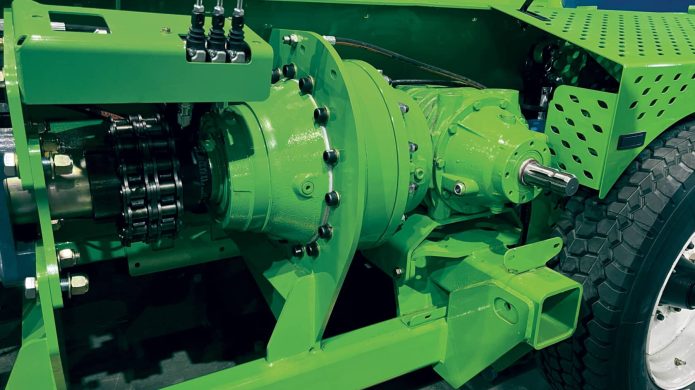

1000-RPM PTO Planetary

The T7270 features a 1000-RPM PTO planetary driveline rated at 200-horsepower. This powertrain consistently generates smooth, durable power to handle varying crop load and crop types.

Serviceability

Serviceability and operation controls have been designed to give operators easy-to-use controls, easy access for machine upkeep, and a cleaner environment.

The Operator Station includes:

- Conveniently located machine controls

- Grease fitting bank for the entire machine

- Oil bracket to store lubrication for chain maintenance

- Easy to open shields for chain inspection

- Integrated toolbox for convenience and storage

Transportation

The T-Series introduces a better way to transport Ag-Bag Pull-Type Baggers. The new hitch design changes towing direction placing the tunnel on the side of the road to keep the tunnel out of the on-coming lane of traffic. This results in better visibility while maintaining the 8.6-foot travel width. In addition, the T7170 has a hydraulic and manual jack system standard on all machines to quickly change between transport and Ag-Bagging.

Tunnels & Tunnel Extensions

T7170 comes standard with either a 9-foot or 10-foot tunnel. A 9-foot or 10-foot Middle Tunnel Extension is also available as an option. With the middle tunnel extensions, the crop can be packed against steel for greater compaction and density before moving into the Genuine Ag-Bag. The tunnel extensions also stack on top of the base tunnel and are moved with the bag cradle. This provides for narrow transport width.

The Feed Quality Solution

Ag-Bag has pioneered the system and the solution for creating the high-quality feed. It goes way beyond simply putting feed in a bag. It means having the right machine, the right packing design, along the bags and inoculants designed to complete the process.

Ag-Bag Plastic was founded by a group of people dedicated to supplying high-quality plastics. Our highly-trained sales staff and the best raw materials available make us the leading manufacturer of high-quality polyethylene materials. After all, plastics are our business.

Your forage is more valuable than ever before. Ag-Bag by RCI recommends protecting your forage crop by using Ag-Bag Boost, an enhanced forage inoculant. Both water soluble and dry inoculate are available to protect your forage and ensure top quality feed.